We get asked all the time about the mechanism for locking the arm on the Leyland and Marshall tractors. This locking mechanism is used for ‘parking’ the linkage when a tractor is not in use, or when carrying out repairs or adjustments to a mounted implement in the raised position.

We get asked all the time about the mechanism for locking the arm on the Leyland and Marshall tractors. This locking mechanism is used for ‘parking’ the linkage when a tractor is not in use, or when carrying out repairs or adjustments to a mounted implement in the raised position.

It is often incorrectly thought that this plunger control mechanism is for keeping the arms up during transport. This can cause damage and even break the top castings, which we see quite a lot here at Tractor Spare Parts. When the arms are locked up, but the main control lever it is not in the lift position the arms and implement are being held up by this tiny mechanism, which puts strain on the back castings, and crack! The pin breaks or worse the casting breaks.

I quote from the Operators handbook for the Leyland 272 model, (although all of the operators handbooks pretty much say the same thing):

‘When moving mounted implements you should move the main hydraulic control lever to its full ‘LIFT’ position. ‘DRAUGHT’ or ‘POSITION’ may also be selected. DO NOT engage the rocker shaft locking plunger. The rocker shaft locking plunger should only be engaged for ‘parking’ the linkage when the tractor is not in use, or when carrying out repairs or adjustments to a mounted implement in the raised position. ‘

We also get customers who are struggling to get their arms to lower, and it is often because of this plunger locking pin getting broken that causes this. We will discuss this later in the blog.

Remember – ‘Parking’ not Transport!

The plunger locking mechanism works by locking the arms in the up position. On the Nuffield tractors there are two different mechanisms – the early and late types.

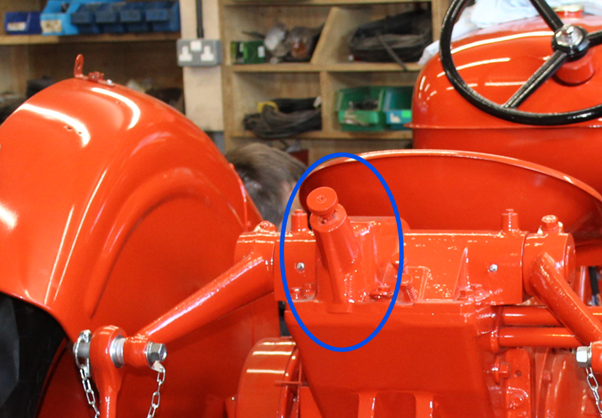

Early Nuffield Tractor

The early Nuffield tractors (up to the Universal 3 and Universal 4 models) have a round knurled knob that turns and goes into the casting. When the arms are raised it lifts the pin slightly and then locks it into position (you see the plunger coming out towards you a bit and then going home) and the arms will no longer go to the down position.

To unlock the arms this plunger needs to be turned and pulled out again, which will allow you to lower the arms. The picture below shows this early plunger mechanism, which is circled in blue on the picture.

Later Nuffield Tractors

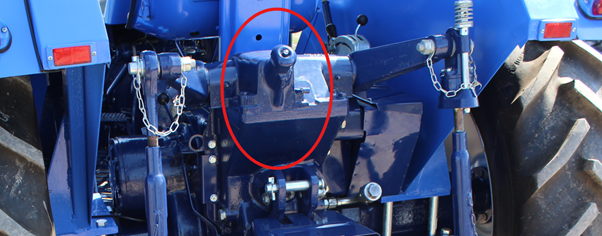

The later Nuffield tractors (from the Nuffield 10/60 onwards) have a slightly different plunger which has a pressed steel domed D-shaped locking cap.

The correct mechanism for engaging this rocker shaft locking plunger is described in the Operators handbook, and I quote from the Leyland 272 Operators handbook below:

‘With the hydraulic pump working, place the main hydraulic control lever in its maximum ‘LIFT’ position. Select ‘DRAUGHT’ with the position and draught control lever. Move the main control lever back along the quadrant about 25 to 38 mm (1 to 1 ½ inches) until the pressure relief valve can be heard to operate. Lift to turn the plunger cap until the flat of the cap is towards the right-hand lift arm, then release the cap ensuring that its flat registers over the flat of the housing casting. Return the main control lever to its maximum ‘LIFT’ position.’

This is the description from the Leyland 272 Operators handbook. Please check your specific model handbook to ensure that it works in the same way.

The picture below shows this later type plunger mechanism with the D-shaped locking cap.

This later type is fitted to the Nuffield models from the Nuffield 10/60 onwards, All the Leyland Middleweight and Leyland Heavyweight tractors and the Marshall Harvest Gold tractors too.

Why is this not a transport lock? Wouldn’t that make sense?

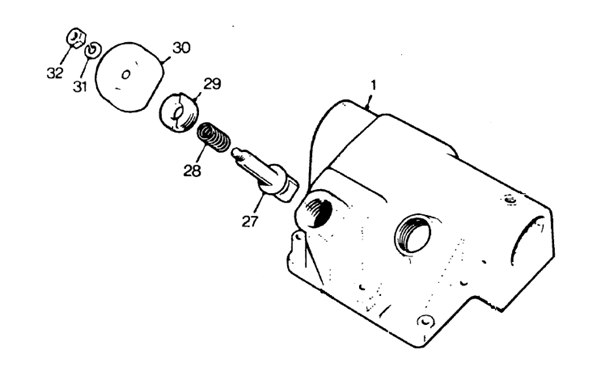

So the question is often posed as to why this plunger locking mechanism is not a transport lock, and to answer this question you really need to understand the components that make up the plunger locking mechanism and how fragile it is. So, let’s explore that now, focusing on the later type mechanism with the D-shaped locking cap.

The D-shaped locking cap is held on with a nut and washer, so they are easily lost if the nut becomes loose. Underneath this D-shaped cap is a retainer which screws into the casting. When you remove this there is a spring underneath, so be careful it does not all spring out if you remove the cap. Then you will see the plunger itself (item 27 on the drawing below). It is this plunger that has a flat paddle on it, and this paddle locates to lock the arms in the up position.

This plunger locking pin, part number AT6401, is what holds the arms up, as the flats of the locking pin engage and lock the arms in the up position.

We have two problems that occur with this plunger locking pin –

- the back castings get smashed when the locking pin is used incorrectly

- the locking pin breaks off and the locking pin goes into the casing and the back arms will not go down.

If the back casting gets smashed then it will be obvious that there is a problem and you will be looking to purchase a new casting.

If the threaded plunger pin has broken at the thread, then the pin may have dropped into the casting and the arms will be stuck. This is often then situation when the arms are stuck and customers call us when they cannot get their arms down, even when they have pulled the cap out.

So how can you prevent this?

The only way to prevent breakages is to use the lock properly and to educate users of the tractors as to the purpose of the locking pin. It is often people borrowing the tractor who cause damage.

If you remember that on the Nuffield and Leyland tractors the plunger locking mechanism is only to be put into the lock position to ‘park’ the linkage when the tractor is not in use, or when carrying out repairs or maintenance to a raised implement and that it is not to transport implements on the linkage, then you will be fine.

Safety first – do not forget to use the lock when you are servicing the implement.