Once you have done an engine rebuild, reconditioned your cylinder head or even once you have replaced the head gasket on an older tractor, there will be settings that you need to make on your engine in order for it to run properly. The best place to find these settings is in the workshop manual where the torque settings and settings procedures is laid out in a nice format. You can find all of the available Nuffield, Leyland and Marshall workshop manuals on our website under the Tractor Workshop Manuals and Handbooks section.

One of the settings that we are always being asked about is the valve clearance adjustment. Setting the valve clearance is important as this clearance compensates for the expansion of the various engine components as the engine heats up, and as a result allowing optimum engine performance and preventing damage to the engine. Therefore, it is very important to set this valve clearance.

If the valves are out of adjustment, you may hear a loud tapping or clicking sound as the engine is run. If there is too much valve clearance then the valves are likely to clatter and in the long-term this will likely cause damage to the valves, camshaft, and rocker arms. If there is not enough valve clearance then the valves will not close properly and this will cause excess heat and the engine will lose power.

It is recommended by BMC and Leyland that when you check the valve clearance (sometimes called the tappet clearance) that you do this when the engine is cold and then again when it is hot. It is important to check the clearance in both cold and hot states.

Thankfully the information to do this is easy to remember – use the rule of 9 and 0.013” hot and cold. That is all you have to remember.

What is the rule of 9?

The rule of 9 is a way of remembering which order to set the valve tappets on a 4-cylinder engine. This doesn’t just work for 4-cylinder BMC engines and 4-cylinder Leyland engines, but also for other 4-cylinder engines too.

For 6-cylinder engines, such as the Leyland 6/98, and BMC 5.1 and BMC 5.7 you use the rule of 13, as is the case for most 6-cylinder engines.

Just for completeness here I ought to say something about 3-cylinder engines, such as the BMC 2.6 and BMC 2.8 engines. Well basically these simple rules go out of the window for these 3-cylinder engines, so just go with what it says in the workshop manual.

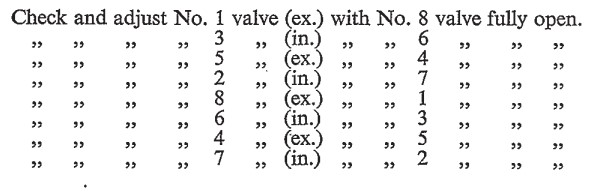

So back to the 4-cylinder engines, specifically the BMC 3.4, BMC 3.8 and Leyland 4/98 engines, which are all an eight-valve engine. We use the rule of 9 for these engines and it basically means that starting from the front of the engine if number 8 valve is open, you subtract 8 from 9 (rule of 9) and the answer is 1. So, you adjust the clearance of valve number 1. If valve number 6 is fully open, then you adjust valve number 3 (9-6=3rd valve). If valve number 5 is fully open then you adjust valve number 4 (9-4=5th valve) and so on. The easiest way to do this is to work through the valves in the order that they open and do the adjustment as they open.

Here is a table that is found in the workshop manuals, which are a handy source of information for the rebuild of a BMC or Leyland engine.

What is the tappet (valve clearance) settings for the Nuffield and Leyland tractors?

The parts book states that the valve clearance should be 0.013” (13 thousands of an inch) both hot and cold. So, you adjust the valve clearance to 0.013”. If you work in the metric system, then this is 0.33mm.

The workshop manual states that the clearance between the ends of the valve stems and the heads of the rockers should be adjusted after valve reconditioning before running the engine and checked again after warming the engine. We recommend that you actually check the valve clearance 3 times – once when the engine is cold, once when the engine has been running for about 5 minutes and it is warm, and again when the engine is up to temperature, and it is hot. It is well worth doing this 3 times, even though it may seem like a lot of work. Thankfully, this co-insides with our recommendations about tightening down the cylinder head after replacing the head gasket. The modern composite head gaskets work best when they are tightened down three times – cold, warm, and hot. So, while you are checking the head three times you might as well check the valve clearance!

The clearance of the valves should also be checked periodically during service.

How do you set the valve clearance?

We always recommend that you use the workshop manuals when working on any Leyland or BMC engine, but a basic procedure is described here.

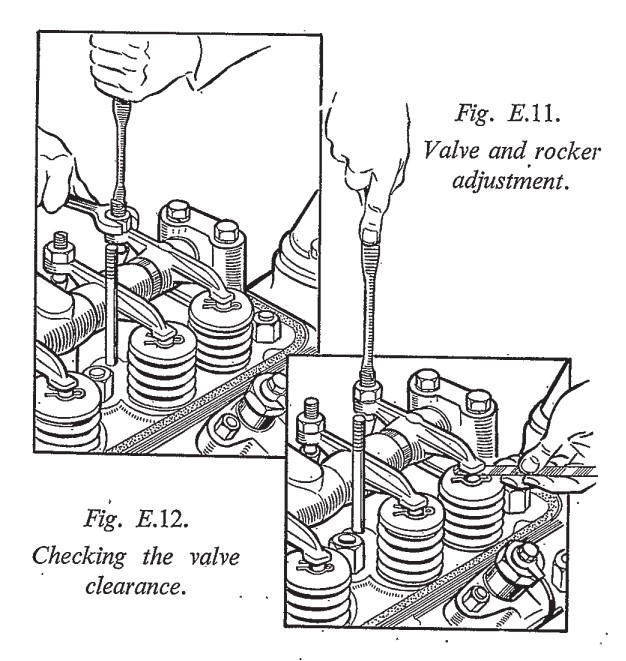

1) First you release the rocker adjusting screw by slackening off the locknut while holding the adjusting screw against rotation with a screwdriver (Figure E.11).

2) Put a 0.013” (0.33 mm) feeler gauge between the valve stem top and the rocker (Figure E.12). Screw down the adjusting screw to allow the feeler gauge to have a light ‘drag-through’ clearance and lock effectively without using too much force.

3) Again, check the clearance to make sure that the setting has not been altered by the locking process.

4) Check and adjust the remaining valves in the same way, using the rule of 9 as a guide for the order in which to check the valve adjustment.

5) Replace the rocker cover and ensure that the joint gasket is in good condition and provides an oil-tight joint. When fitting cork gaskets such as the rocker cover gasket, we recommend using Hylomar Blue non-setting gasket compound on both sides of the gasket. This will make a nice tight seal.

What parts are available?

Most of the time the valves are checked and replaced where appropriate upon an engine restoration. The inlet valves, exhaust valves, rockers and all other head components are available for the BMC 3.4, BMC 3.8 and Leyland 4/98 and they are all listed on the Tractor Spare Parts Ltd website.

The rocker arm, part number AMK1756, is available as a new part as is the valve tappet, part number AMK20 itself. These parts are the same and they use the same part number across a number of BMC and Leyland engines.

Whatever parts you need for your BMC 4 cylinder or Leyland 4/98 engine Tractor Spare Parts Ltd have you covered. We have the majority of parts listed on our website where you can order direct for fast and easy delivery. If you cannot find what you want on the website or if you just want to chat to somebody who knows what you need then get in touch with us as we are real people and like to deal with customers on the phone in a personal way.