We are always speaking to customers about problems with engines, the reasons why they are experiencing problems with their engines and how we can help to get their BMC engine or Leyland engine back up and running. One thing that we hear a lot is water in the sump, which forms a milky solution and suggests the engine needs attention.

There are many reasons why the water and oil would be mixing. The head gasket may have gone, and split between the liners, or it may be a case of porous liners. But what do we know about ‘porous’ liners – what causes them, what are the symptoms and what can we do about it to rectify the problem?

Wet vs dry cylinder liners

We are quite often asked if the BMC and Leyland engines have wet or dry liners and what the difference is. Well, it is as simple as it sounds. Dry liners do not come into direct contact with the cooling system of the engine but are surrounded by the metal of the engine block. Wet engine liners come into contact with the cooling system and are usually heavy and thick-walled liners that are fitted into the engine block with hand pressure and are sealed with liner seals.

The BMC and Leyland engines are fitted with these wet liners, which are prone to corrosion and becoming porous if the cooling system is not checked regularly and replaced within the guidelines of the anti-freeze.

Porous liners

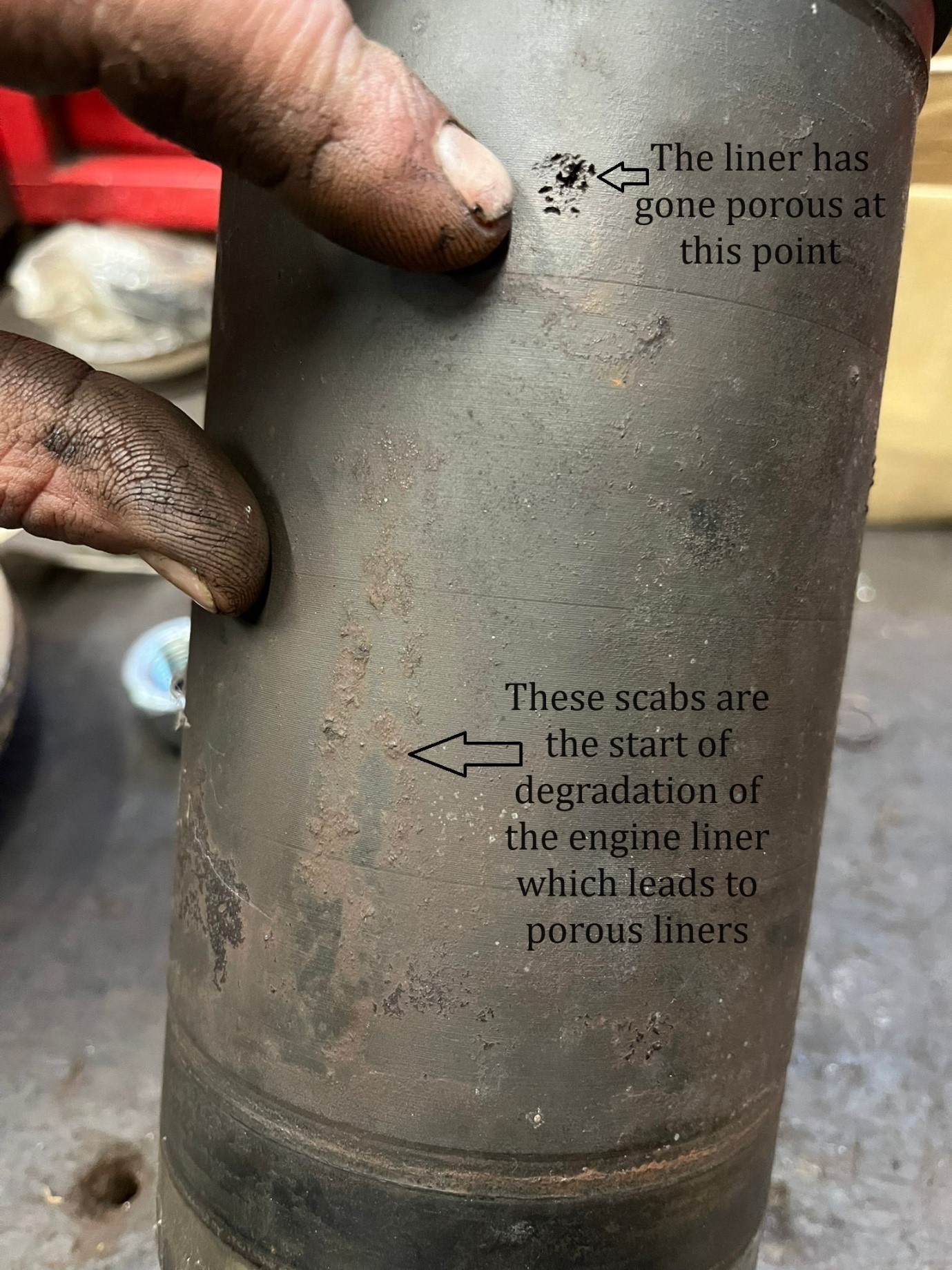

Porous liners are exactly as they sound; little holes have formed in the cylinder liners because of corrosion and these holes in the liners allow coolant through into the lubricating oil. But what causes this?

Pitting of the liners is generally caused by improper maintenance of the cooling system in a diesel engine. People may say that they have anti-freeze in their engine, and they check its concentration every year, so why is this not good enough? Well simply put anti-freeze does exactly what it says on the tin and stops the cooling fluid from freezing in the cold weather. But this anti-freeze functionality does not prevent corrosion. However, modern anti-freeze does contain corrosion-inhibitors if it is replaced regularly. For the Nuffield, Leyland and Marshall tractor engines we recommend the blue anti-freeze, and we use the anti-freeze from Pennine Lubricants. This has added chemicals which protect against corrosion for 2 years, after which the anti-freeze should be replaced with fresh. This is the type of maintenance to the cooling system that will prevent corrosion of your diesel engine and prevent porous liners.

What is pitting and porous liners?

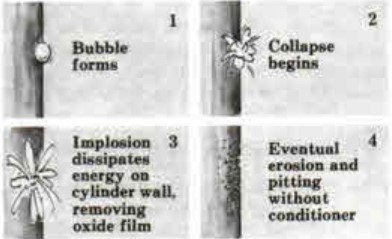

Corrosion is a form of electrolysis which causes cylinder wall material to deteriorate. When the corrosion happens it forms an oxide film which then protects the engine liner from further deterioration. However, this film in reality doesn’t stay on the outside of the liner for very long. Air bubbles in the cooling system form around the film and they then implode (the opposite of explode – they explode but inwards) and as this happens sufficient energy is released to physically clean the cylinder wall, remove the oxide film (which is slow to reform) and this allows further corrosion and pitting to take place at a high rate.

This corrosion takes place on the outside of the cylinder liners, and when the corrosion gets too bad it can reach through the cylinder liner wall and cause porous liners, where there are holes through the liner from the outside to the inside. This cavitation is what we call porous liners as it allows the contamination of the cooling fluid and the lubricating oil.

What can we do about porous liners?

Apart from the best solution being prevention which involves changing your anti-freeze every other year so that it also protects against corrosion, porous liners can be sorted. The engine liners in the BMC engines and the Leyland engines are what we call ‘wet sleeve’ liners, which means that they are removeable liners, which come into direct contact with the cooling fluid. This means that they are replaceable items.

An engine rebuild can sort porous liner problems

If you have porous liners in your BMC or Leyland engine, you can replace the engine liners, in an engine rebuild and away you go again. Your rebuilt engine will be good for another 30 or 40 years, as long as you look after the cooling system.

Here at Tractor Spare Parts Ltd we can help you with an engine kit, or the individual components if you do not require everything, for your Nuffield, Leyland or Marshall tractor. We just need the engine serial number off the side of the block (see this blog on serial numbers for where to locate the serial number)

The engine kits contain everything that you will need for a basic engine rebuild. An example of kit contents is listed below (This is the engine kit contents for an early Leyland 4/98 engine)

4 x Piston & pin

4 x Piston ring set

4 x Engine liner

4 x Liner seal set

4 x Liner shim at 0.003"

4 x Small end bush

1 x Head gasket (including valve stem seals)

1 x Bottom set

1 x Front crank seal

1 x Rear crank seal

Our engine kits are designed as a basic engine rebuild kit, and, of course, no two engines are the same. Here at Tractor Spare Parts Ltd, we offer all components for these BMC and Leyland engines fitted into the Nuffield, Leyland and Marshall tractors, so If you require anything outside of the basic engine kit we can help you.